PATCH WITH ANTI-CALCIUM PROTECTION

CARDIOPLANT XENOPERICARDIAL PATCH

Cardioplant

Xenopericardial patch

Xenopericardial patch

Size

the product can be made of any size and any geometric shape within the maximum area (100 cm2).

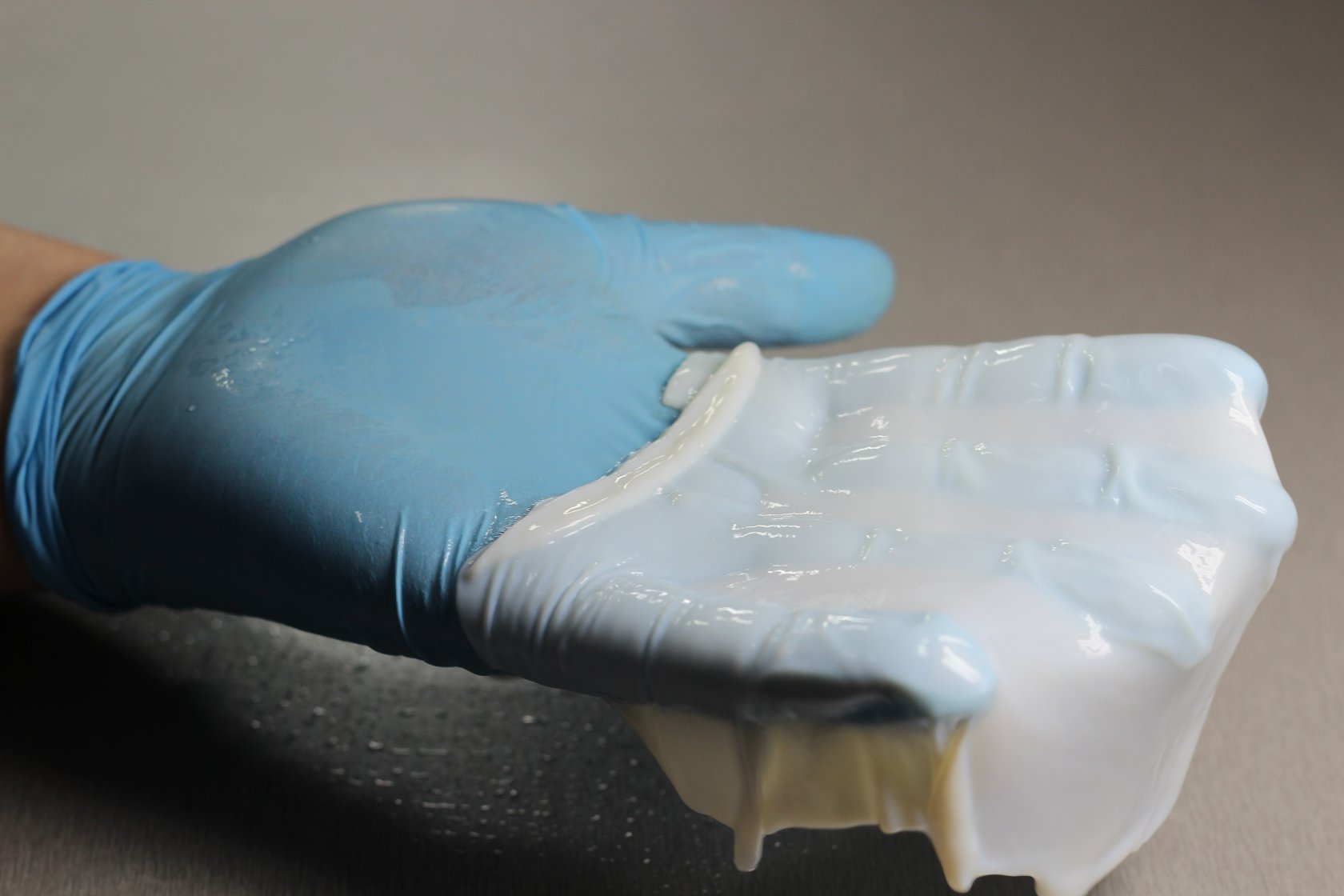

Patch based on decellularized highly purified pet pericardium for plasty of intra and pericardial tissues. The raw material for manufacturing the product undergoes a complex multi-stage chemical and biological processing according to a patented technology using anti calcium matrix-saving techniques. Due to this all carriers of antigenicity - cellular elements and glycosaminoglycans of the intercellular matrix are completely removed from the biotissue. The structural architectonics of fibrillar proteins remains intact. This allows the patch to act as a matrix for colonizing recipient cells, transform into its own healthy tissues and metabolize according to the laws of natural processes. The patch is absolutely biologically-compatible. The patented technology of anti-calcium treatment prevents the formation of insoluble deposits of calcium salts by screening. During 11 years of using the product in more than 80 clinics, no cases of calcification of the product were detected. It has a two layer structure –a smooth resistant side and a woolly, capable for active integration.

It is supplied in a specially developed preservative solution that does not require long term washing. For convenience the delivery set includes sterile accessories — a washing container and a disposable tweezer.

Patch based on decellularized highly purified pet pericardium for plasty of intra and pericardial tissues. The raw material for manufacturing the product undergoes a complex multi-stage chemical and biological processing according to a patented technology using anti calcium matrix-saving techniques. Due to this all carriers of antigenicity - cellular elements and glycosaminoglycans of the intercellular matrix are completely removed from the biotissue. The structural architectonics of fibrillar proteins remains intact. This allows the patch to act as a matrix for colonizing recipient cells, transform into its own healthy tissues and metabolize according to the laws of natural processes. The patch is absolutely biologically-compatible. The patented technology of anti-calcium treatment prevents the formation of insoluble deposits of calcium salts by screening. During 11 years of using the product in more than 80 clinics, no cases of calcification of the product were detected. It has a two layer structure –a smooth resistant side and a woolly, capable for active integration.

It is supplied in a specially developed preservative solution that does not require long term washing. For convenience the delivery set includes sterile accessories — a washing container and a disposable tweezer.

- For endoventriculoplasty in postinfarction aneurysms of the left ventricle

- central pulmonary anastomosis

- plastic surgery of the aortic root for Nicks-Nunez when prosthetics of the aortic valve

- correction of aortic coarctation

- plastic surgery of atrial and ventricular septal defects

- radical correction of the Fallot's tetrad

- reconstruction of mitral and aortic cusps of valves

- plasticy of the vascular wall, aorta and atrial wall

- plasticy of the recipient's pericardium

The product is a chemically-biologically processed parietal leaf of the pericardium of a calf. Animals undergo a strict veterinary and sanitary examination, confirmed by a veterinary certificate. To date there is no objective evidence that the type of animal (pig, cattle, horse, sheep) that is the source of raw materials for the manufacture of patches can directly affect the biological compatibility and safety of the product (it can affect the physical and mechanical parameters due to different anatomy). To the maximum extent, this depends on the processing that the raw material goes through. After deep cleaning and processing the material is almost transformed into a biological polymer. There are hundreds of ways and dozens of approaches to pericardial processing. All methods that have proven their effectiveness in clinical practice are based on the decellularization procedure and maximum preservation of native tissue architectonics. Therefore, experienced specialists do not pay attention to the source of raw materials when choosing a patch, but look at the clinical effectiveness of the product in the long term postoperative period.

A unique patented method of chemical-enzymatic processing of raw materials allows to completely destroy and remove from the tissue cellular elements and glycosaminoglycans of the intercellular substance as the main carriers of antigenicity. Processed biological tissue, devoid of cells and species specificity, has excellent biologically-compatible properties. Patch acts as a matrix for settling recipient cells, vascularized, transformed into its own healthy tissues and metabolized according to the laws of natural processes. The patented technology of anti-calcium treatment prevents the formation of insoluble deposits of calcium salts by screening. During 11 years of using the product in more than 80 clinics, no cases of calcification of the product were detected.

Structural proteins retain their architectonics after processing. Stabilization with a cross linking agent turns the biological tissue into a strong biopolymer due to the formation of strong cross links. Due to different variants of xenopericardial processing, it is possible to produce a biomaterial with specified elastic-deformative properties. The elastic coefficient can vary from 5 to 35 MPa. The maximum load – from 15 to 40 N. Xenopericardium with different properties allows to solve problems of tissue replacement in a variety of clinical cases.

The xenopericardial plate has two different surface properties. The serous surface of the plate has a smooth sliding surface and bioresistance. It is not soldered to the surrounding tissues in the body. The fibrous surface of the xenopericardial plate is woolly, actively fuses with tissues and has high biointegration. It is possible to produce a plate with a smoothed fibrous surface. The patch manufacturing technology uses a non contact thickness gauge and laser pattern. This allows to accurately and error-free cut a uniform thickness of biomaterial of any geometric shape.

Xenopericardial plate is an effective biological material for soft tissue plasticy in many areas of reconstructive surgery. This is a biological material with a wide range of applications. It is used to replace the affected areas of defects in organs and tissues. The properties of the patch allow the xenopericardial plate to act as a matrix for colonizing cells of surrounding tissues. The latter are actively integrated into the implant and produce extracellular matrix molecules. In this way the biological implant is involved in the metabolism and replaced with newly formed healthy connective tissue. To prevent calcification, the xenopericardial plate in contact with the bloodstream undergoes a specially developed anti calcium treatment, which reduces the calcium-binding activity of the implant, while the treatment does not affect the physical and mechanical properties of the biomaterial. The effectiveness of the developed anti calcium treatment of xenopericardium has been proven by long term clinical observations.

The patch is delivered in a convenient individual (double sterile) package. The delivery set includes a single-use sterile tweezers and a single-use sterile bath for washing in saline solution. At the customer's request the necessary suture surgical material can be included in the delivery set. The thickness of the product according to the marking: XP/T – 0.3-0.5 mm, XP/L – 0.5-0.8 mm.

The maximum area of the plate is 100 cm2. The xenopericardial plate manufacturing technology uses a non contact thickness gauge and a laser pattern. This allows to accurately and error-free cut a uniform thickness of biomaterial of any geometric shape. The plate is supplied in a proprietary preservative solution, which does not require long preoperative preparation. The duration of washing in a sterile saline solution is 4 minutes.

The maximum area of the plate is 100 cm2. The xenopericardial plate manufacturing technology uses a non contact thickness gauge and a laser pattern. This allows to accurately and error-free cut a uniform thickness of biomaterial of any geometric shape. The plate is supplied in a proprietary preservative solution, which does not require long preoperative preparation. The duration of washing in a sterile saline solution is 4 minutes.